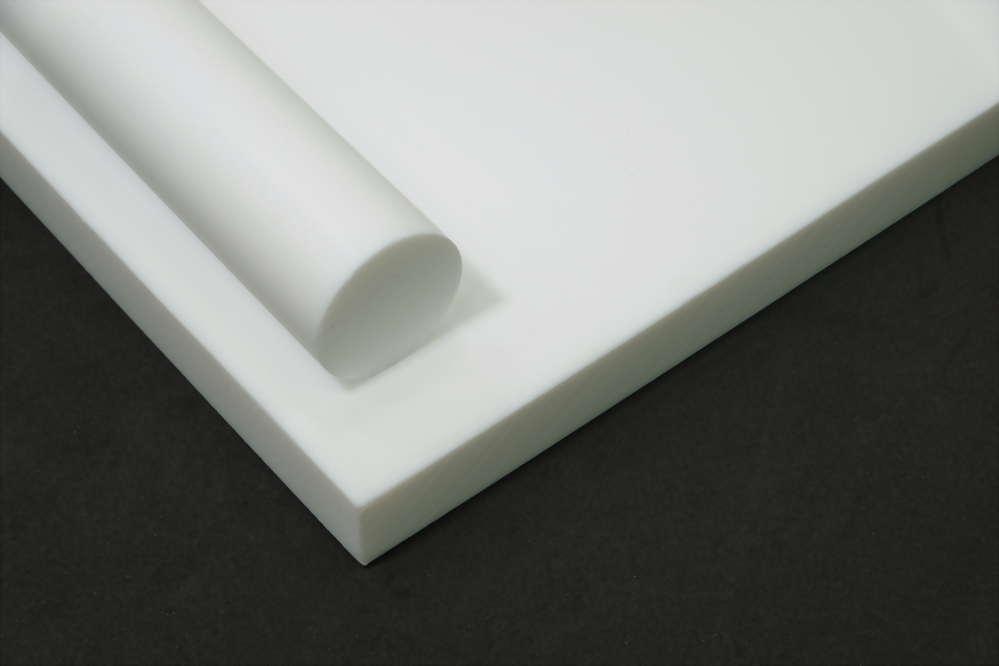

PTFE

1. high max. allowable service temperature in air ( continuously 260°C )

2. excellent chmical and hydrolysis resistance

3. good wear resistance

4. low coefficient of friction

5. very good dimensional stability

6. physiologically inert ( only applies to FLUOROSINT 207 )

7. good electrical insulating properties

8. oustanding UV- and weather resisance

9. inherent low flammability

Standard :

‧Round ros

‧Ring & tubes

‧Plates

G400 :

The prototype of TFE.

G403 / G405 ( Glass fiber added ) :

15% glass fiber is added to G403; 25% glass fiber is added to G405, which enhances abrasion resistance and chemical resistance but is not resistant to strong acid and alkali.

G412 ( Graphite added) :

G412 has 15% graphite added, it has very low friction coefficient, good compressive strength and wear resistance.

G415 (Carbon added) :

G415 added 25% carbon, has good thermal conductivity and resistance to deformation.

G453 (Carbon and graphite added) :

G453 has 25% carbon and graphite added, has very low friction coefficient, good compressive strength and wear resistance, and also has good heat transfer and deformation resistance.

G458 (Copper added):

G458 has a very low coefficient of friction, good compressive strength and wear resistance, and good thermal conductivity.

PFA :

Compared with PCTFE, PVDF, etc., PFA has excellent chemical resistance, and is insoluble to all chemical agents.

Non-corrosive, low flammability, can be exposed to strong ultraviolet light for a long time.

PCTFE :

Because it has good transparency and very small moisture permeability, it is often used in pharmaceutical packaging and electroluminescence.

, On the packaging of precision electronic parts. It has good low temperature properties, airtightness, and dimensional stability.

FLUOROSINT 500 has nine time greater resistance to deformation under load than unfilled PTFE ( tested under a stress of 14 MPA at 50°C ). Its coefficient of linear thermal expansion approaches the expansion rate of aluminium and is 1/5 that of vigin PTFE. It is considerably harder than virgin PTFE, has better wear characteristics and maintains low frictional properties. FLUOROSINT 500 is also non-abrasive to most mating materials.

PTFE 207 (White) (PTFE + mica):

The composition of the raw material used for the production of FLUOROSINT 207 is suited for food contact according to the EU/FDA regulations. In combination with a good mechanical performance and an inherent outstanding chemical and hydrolysis resistance, this feature opens numerous application possibilities in food, pharmaceutical and medical industries.

FEP :

Due to its excellent heat resistance and electrical characteristics, it is non-flammable in industrial cables, electronic equipment wiring, flat cables and other wires.

繁體中文

繁體中文 English

English