PI

Main Characteristics :

1. extremely high max. allowable service temperature in air ( PI-1 : 240°C continuously, with short term excursions up to 450°C )

2. excellent retention of mechanical strength, stiffness and creep resistance over a wide range of temperatures

3. good sliding properties and excellent wear resistance

4. very good dimensional stability

5. inherent low flammability

6. good electrical insulating and dielectric properties ( only applies to PI-1 )

7. low outgassing ( except water )

8. high ionic purity level ( PI-1 )

9. excellent resistance against high energy radiation

Standard :

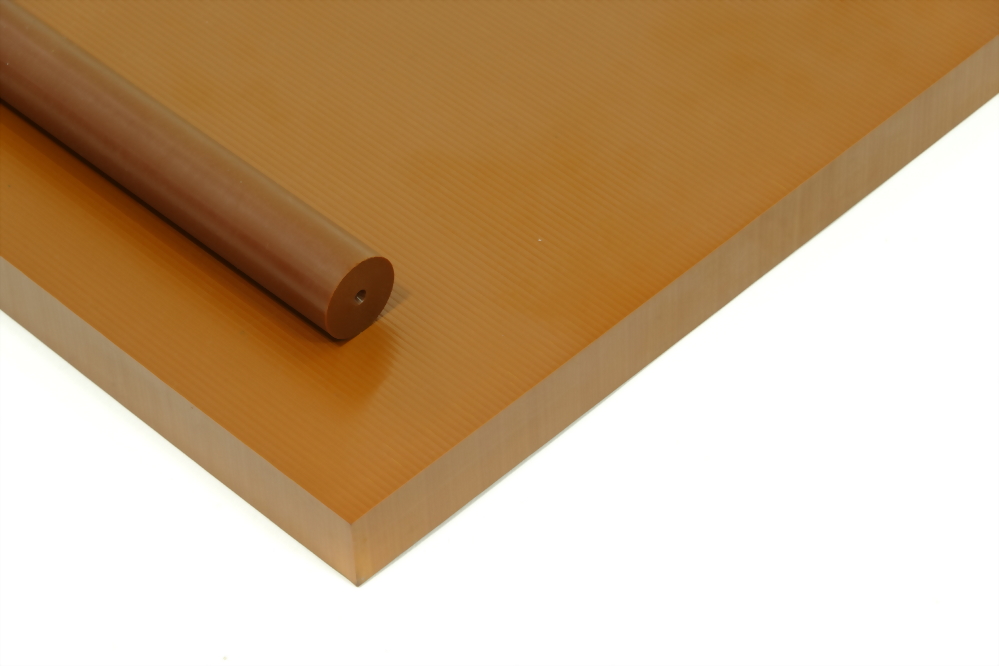

‧Round ros

‧Ring & tubes

‧Plates

1. extremely high max. allowable service temperature in air ( PI-1 : 240°C continuously, with short term excursions up to 450°C )

2. excellent retention of mechanical strength, stiffness and creep resistance over a wide range of temperatures

3. good sliding properties and excellent wear resistance

4. very good dimensional stability

5. inherent low flammability

6. good electrical insulating and dielectric properties ( only applies to PI-1 )

7. low outgassing ( except water )

8. high ionic purity level ( PI-1 )

9. excellent resistance against high energy radiation

Standard :

‧Round ros

‧Ring & tubes

‧Plates

PI ( chestnut ) :

This is the unfilled base resin which provides maximum physical properties and best electrical and thermal insulation.

PI + graphite 15%( grey-black ) :

This grade contains 15% graphite, added to provide long wear and low friction.

The incorporation of 15% graphite and 10% TEFLON® results in a VESPEL grade that exhibits the lowest coefficient of friction over a wide range of operating conditions and also has got the lowest wear rate up to 150°C.

PI + MoS2 ( grey-black ) :

With 15% of molybdenum disulphide, this VESPEL grade provides internal lubrication for seals and bearings in vacuum or inert gases ( dry environments ).

This is the unfilled base resin which provides maximum physical properties and best electrical and thermal insulation.

PI + graphite 15%( grey-black ) :

This grade contains 15% graphite, added to provide long wear and low friction.

PI + graphite 40% ( grey-black ) :

This grade containing 40% graphite has the wear and friction properties of PI-21 combined with improved dimensional stability (lowest coefficient of thermal expansion ).

The incorporation of 15% graphite and 10% TEFLON® results in a VESPEL grade that exhibits the lowest coefficient of friction over a wide range of operating conditions and also has got the lowest wear rate up to 150°C.

PI + MoS2 ( grey-black ) :

With 15% of molybdenum disulphide, this VESPEL grade provides internal lubrication for seals and bearings in vacuum or inert gases ( dry environments ).

繁體中文

繁體中文 English

English